Shunxin 3-6t/h whole set of DAP fertilizer production machines for sale

Dap is the abbreviation of diammonium phosphate which is the main raw materials of dap fertilizer production process. Like map, sop, and urea fertilizer, dap fertilizer manufacturing process is a kind of compound fertilizer production line. Therefore, if you want to convert solid powdery dap fertilizer into granular dap fertilizer, Shunxin could provide you whole set of machines.

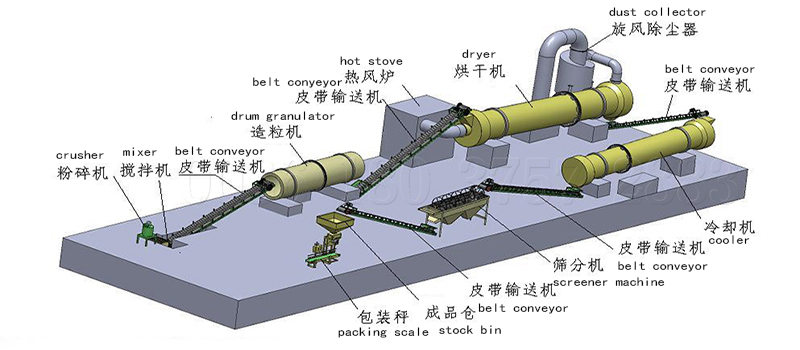

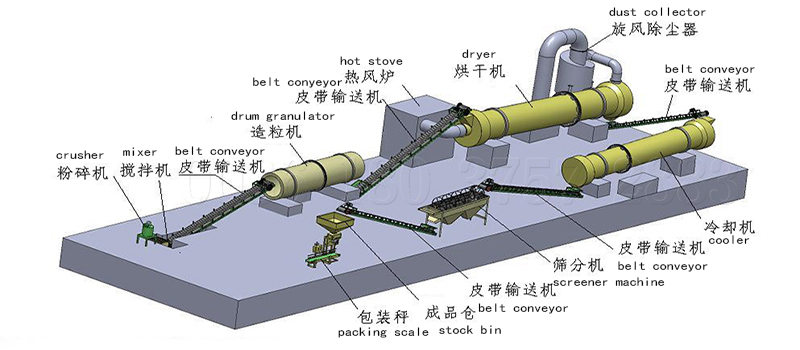

In general, dap fertilizer manufacturer mainly needs fertilizer crusher, fertilizer batching equipment, mixer, fertilizer granulator and packing machine. Besides, the company also designs screening machine, drying machine and cooling machine for diammonium phosphate fertilizer manufacturers. The fertilizer equipment from Shunxin Heavy Industry can perfectly meet your requirements for making compound dap fertilizer. What’s more, the capacity can be customized. The largest capacity is 30t/h. If you have interest, welcome to contact us any time. Or you can directly visit our factory in your free time.

What dap fertilizer production process do you want?

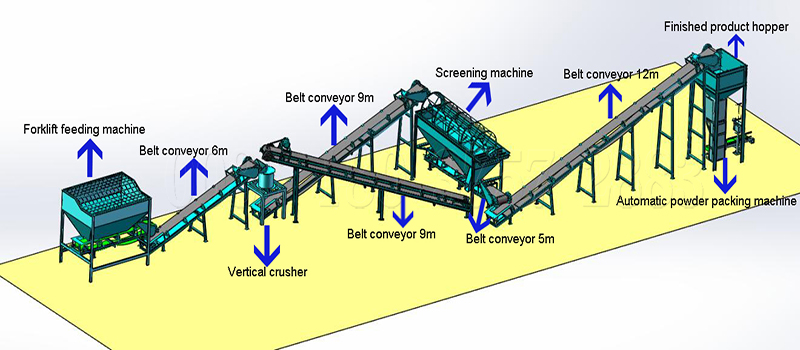

To be honest, Shunxin fertilizer equipment could perfectly process your solid dap fertilizer. Furthermore, there has two different types. The first is to make solid dap fertilizer into powder dap fertilizer. The second is to transfer solid dap fertilizer into dap fertilizer pellets. Shunxin supplies complete machines for both different dap fertilizer.

If you choose to make powder dap fertilizer, the complete fertilizer equipment is fertilizer crush machine, fertilizer mixer, screener and fertilizer packing equipment. However, consumed you plan to start granular dap fertilizer making, there is more complex than powder dap fertilizer. In addition to the mentioned fertilizer making machine, it is necessary to prepare fertilizer pelletizer for diammonium phosphate production process. Besides, for higher quality dap fertilizer pellets, fertilizer drying and cooling machine is also indispensable.

What compound fertilizer granulator is best for your granular dap fertilizer production process?

Shunxin compound fertilizer granulator refers to pan granulator, rotary drum granulator, and double roller granulator. The 3 fertilizer granulation machines could meet your requirements in small, middle and large scale dap fertilizer granules manufacturing process. What’s more, the balling rate is more than 93%.

25t/h large capacity rotary drum granulator: SXZGZ-3210

Shunxin rotating granulator is usually applied to large scale fertilizer production line. Especially, it is very popular with compound fertilizer plants, such as: npk compound fertilizer production and dap fertilizer production process. It can make your dap fertilizer materials into specific shape. The main operation way of Shunxin drum pelletizer is wet granulation. That is through certain water or steam, dap powder fertilizer is fully reacted in chemical way after wet inside of cylinder body. And then, under centrifugal force, dap materials will finish granulating process.

- Model: SXZGZ-3210

- Power: 37kw

- Diameter: 3200

- Installation Angel: 2°-5°

- Rotary Speed: 9.5(r/min)

- Capacity: 15-30

0.8-1.2t/h small capacity pan granulator: SXYZ-1800

You can also name it as disc pelletizer, because its appearance looks like a plate. Shunxin disc granulator adopts the whole circular arc structure, which has three discharging ports. Therefore, you can granulate dap fertilizer discontinuously. Furthermore, through controlling the reducer, you can control pan pelletizer pelletizing speed. In a word, it is an ideal equipment in organic fertilizer production and compound fertilizer manufacturing.

- Model: SXYZ-1800

- Edge Height: 300mm

- Rotary Speed: 21(r/min)

- Capacity: 0.8-1.2t/h

- Total Power:3kw

- Dimension: 2060*1700*2130mm

6-8t/h double roller granulator for dap fertilizer production process: SXJZ-3T

It is especially for compound fertilizer granules production like bb fertilizer production and dap fertilizer producing. Compared with other two fertilizer pelletizing facility, Shunxin roller granulator belongs to dry type granulation. That is to say, after dap fertilizer granulation process, there is unnecessary to dry and cool. Besides, different roller sheet will manufacture different shapes dap fertilizer pellets.

Double roller granulator for dap fertilizer production

- Model: SXJZ-3T

- Power: 11-15kw

- Granule Diameter: 3-10mm

- Roller Sheet Size: 300*300mm

- Dimension: 1850*1100*2050mm

- Color: red(can be customized)

If you want to assemble pelletizing equipment for dap fertilizer producing process, Shunxin will be your reliable supplier. Moreover, if you have your own idea in dap fertilizer granulating machine, Shunxin engineers can design customized products for you. So, please tell us your detailed requirements in spare time.

3 Advanced auxiliary fertilizer machines made by Shunxin Heavy Industry is necessary to your dap fertilizer production process

In order to supply higher quality dap fertilizer for your clients, you should install some auxiliary fertilizer equipment. Now Shunxin experts show you which machines is necessary for your dap fertilizer production process.

Solid DAP fertilizer crush machine

Whether you are going to make powder or granular dap fertilizer, it is necessary to crush the solid dap fertilizer. Thus, fertilizer crusher is indispensable. Shunxin designs urea crush machine and cage crusher, which is dedicated for compound fertilizer plants. Both of them could perfectly crush your solid dap materials into fine powder.

DAP fertilizer mixing machine

Fertilizer mixer is used to uniformly mix all sorts matching materials and dap substance into together. This process plays an important role in granular dap fertilizer manufacturing procedures. Therefore, for meeting dap fertilizer manufactures demand, Shunxin designs horizontal mixer, bb fertilizer mixer for you. They can help you to quickly mix 15t/h dap fertilizer evenly.

Fertilizer drying machine for dap fertilizer production process

If you adopt pan granulator or rotary drum pelletizer, your dap fertilizer production line needs assembling a fertilizer dryer. Because, after pelleting dap fertilizer, there will be 20% moisture. For helping you to store dap fertilizer longer time, Shunxin manufactures fertilizer rotary drum dryer, which has large capacity. What’s more, you can easily operate it.

Fertilizer Crusher

Fertilizer Mixing Equipment

Fertilizer Drying Machine

Are Shunxin fertilizer machines expensive for assembling a complete dap fertilizer production process?

It is an inevitable process that we will talk about the question about price in negotiation. About this question, Shunxin promises you we will provide high quality dap fertilizer making machine in a reasonable price. In addition, you also know that there have many factors that will influence your cost.

- Firstly, pan and rotary drum granulation for dap fertilizer manufacturing process will be more expensive than double roll granulation process. Because, you need to buy the matching machine: fertilizer drying and cooling equipment.

- Secondly, different capacity will impact the price. For example, 10-15t/h dap fertilizer production process absolutely costs more than 6-8t/h dap fertilizer making machine.

- Thirdly, the higher quality configurations fertilizer equipment has a higher price than general configurations machine. For instance, if you wan to the granulating machine with motor from German, the investment must be higher than fertilizer pelletizers with Chinese motor.

Therefore, you should consider all aspect before make decision. And as long as you want to buy fertilizer making facility from Shunxin Heavy Industry at any time, there will be the factory price for you. So, if you have interest to start dap fertilizer production business, please contact us in time.