Shunxin granular potassium fertilizer production line

Today, it is a trend to develop the granulator fertilizer. Pellet fertilizers possess good physical performance that is convenient to store and use. At the same time, there is the function of slow release, which can enhance efficiency of fertilizers. At present, in the light of requirement of the modernized agriculture, the demand of granular potash keeps growing all the time. Thence, there is a broad market prospect for the pellet fertilizer manufacturer. If you want to assemble a granular potassium fertilizer production line, the granulating machine is the key equipment. And because of the difference of granulator, here are two kinds of forms to make granular potash, the disc granular potassium production line and extrusion granular potash making line.

Shunxin grasps the opportunity and manufactures a series of granulator. Meanwhile, we also have competence to provide complete machines for the above two mentioned lines. Now the following contents will give you a detailed information for your reference.

The two types of granular potassium fertilizer production line provided by Shunxin

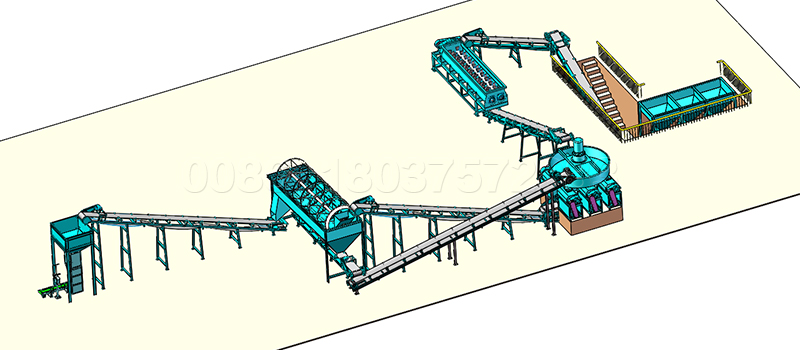

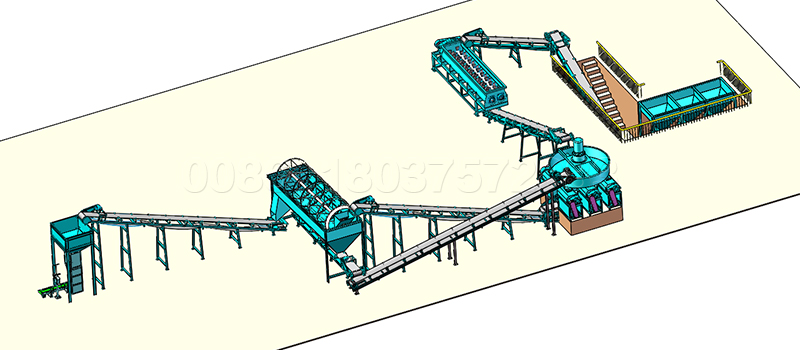

Disc granular potash production line

To be honest, disc granular manufacturing line takes the form of wet granulation. It refers to use the disc granulator to make the powder potash fertilizer into pellet potash. Through this method, you need to put some water or clay to the powder potash manure that help granulate in the process of production. What’s more, the pellet potash fertilizer must contain high moisture. Therefore, there should be a drying and cooling machine after the process of granulating. At present, Shunxin manufactures rotary drum drying machine and rotary drum cooling machine, which can remove the moisture from fertilizer effectively.

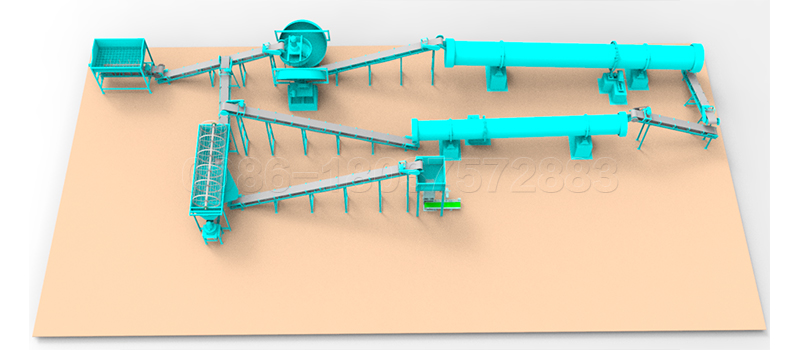

Extrusion granular potash making line

Generally speaking, extrusion granular potash making line uses the form of dry granulation. By the mode of extruding, the powder potash fertilizer is made into granular. In terms of production process, it is more simpler than the disc granulation. The double roller extrusion granulator of Shunxin is especially produced for the extrusion granulation. And if you do not have large invest fund, our experts suggest you choose the extrusion granular production line. So, it needs less equipment, which will cost you a little.

Except for above mentioned granulators, Shunxin has many other types pellet making machines. Therefore, you can use them to establish a specific complete granular potash making flows.

Main machines will be used in granular potash manufacturing line

Available Machines of Shunxin in disc granular potassium fertilizer production line

Fertilizer crusher: before making pellet granular, these raw materials need to be crushed into the state of powder. Shunxin has seven kinds of crushing facility such as the new type vertical crusher, semi-wet material crusher, cage crusher, etc. if you want more detailed messages, please feel free to contact us.

Disc granulator: it is a crucial machine in the whole granular potash manufacturing process. The disc granulator produced by Shunxin is high quality, durable, and never deformed. The most important point is that the granulating rate can reach more than 93%, which is the choose of most manure makers. However, you should know that the cost of this method will cost you more.

Pan Granulator

- Model: SXYZ-1500

- Edge Height: 300mm

- Rotary Speed: 21(r/min)

- Capacity: 0.5-0.8t/h

- Total Power: 3kw

- Dimension: 1760*1500*1950mm

Drying machine: disk granulation is a kind of wet granulating equipment. The moisture in the pellet potash fertilizer may be beyond the standard level. So, you should assemble a dryer behind the granulating machine. The rotary drum drying machine can quickly dry the potash manure.

Cooling machine: after drying, there need a cooler to cool the temperature of fertilizer down. The rotary drum cooling machine matches the dryer and can effectively cool the particles fertilizer.

Fertilizer bagging machine: this machine is used in all the fertilizer production line and always assembled at the end of the processing. Here are the single bucket automatic packing scale and double bucket scale automatic packing scale. Therefore, if your capacity is in large, our experts recommend the later machine.

Bag filling machine for fertilizer packing

- Model: SXH-50

- Function: packing and weighing materials

- Weight: 500kg

- Voltage: 380v

- Packing Speed: 3-4bags/min

- Degree of Automation: fully automatic

Complete ranges fertilizer facilities available in Shunxin for extrusion potassium fertilizer production line

Fertilizer conveyor belt: it takes the function of connecting the materials and the machines. Each fertilizer production line needs many conveyors. Shunxin has three types, the screw conveyor, the mobile belt conveyor and the bucket elevator. You can choose the most suitable one in the light of making flows.

Double roller extrusion equipment: the double roller extrusion granulator enjoys the working principle of dry granulation. And if you choose this method, there is no need to install the drying and cooling machine in the production line. Especially, if you do not have enough funds to invest, Shunxin advises you choose the double roller extrusion machine. It is an ideal choice for the small-scale fertilizer plant.

Double Roller Extrusion Fertilizer Pelletizer

- Model: SXJZ-1T

- Power: 22-30kw

- Granule Diameter: 3-10mm

- Roller Sheet Size: 185*300mm

- Dimension: 1630*850*1650(mm)

- Color: red(can be customized)

Screening equipment: Shunxin develops two kinds of screening equipment, the rotary screening machine and the vibrating screen machine. Both them are of high efficiency.

Fertilizer packing machine: the equipment is as the same with the disc granular potash production line. Based on actual situation of the producing line, you can make decision which one do you need.

Shunxin is a famous equipment manufacturer in china, especially in the fertilizer field. We have rich experience in producing fertilizer making machine. Assumed you want to design the manufacturing line, our company also can provide customized equipment. If you are interest in our facilities, welcome to contact us anytime.

Some advantages for your Granular potassium fertilizer production line by using Shunxin double roller extrusion granulator

- Low energy consumption. Extrusion granulation refers to that the materials is granulated at room temperature. Compared with other granulating methods, there is no need of fuel gas for the drying and cooling machines. Just less water and electric are needed for the production line.

- Low investment. The double roller extrusion granulator belongs to the machines of dry granulation. Thence, you do not have to purchase the dryer and cooler. The relatively simple production processwill save a large amount of money.

- Without adding adhesive. Dry type of granulation utilizes the intermolecular force of material itself to extrude the powder potash fertilizer into particles, which can help the manufacturers save the cost of buying the adhesive.