Starting a mini organic fertilizer production line, you should know what you need to prepare. The budget is a main factor. Here Shunxin provides you information about how to reduce the costs on your organic fertilizer making business. And suitable fertilizer processing machines can help you reduce the small scale organic fertilizer production line cost. There are simple small scale organic fertilizer processing machines in Shunxin for your powdery and granular fertilizer making. Especially, we have different equipment configurations at low cost.

What basic items should you consider on the small scale organic fertilizer production line cost?

Establishing a mini organic fertilizer production line, one thing you should consider is the budget. Actually, the main costs are on raw materials, plant site, labor force and the processing machines. Thus, it is serious for you to do some researches.

- Raw materials: Generally, animal waste, mushroom residue and some agricultural waste are often used as materials for manufacturing organic fertilizers. For your animal farm or plant growing farm, you can recycle your organic waste directly. Or it is also suitable for you to buy materials from them.

- Plant site: As for the plant site, you can manufacture in your own farm or rent a small plant for your mini organic fertilizer production line.

- Employees: Manufacturing organic fertilizer is a long-time business. The labor force also influences your cost. The more the employees, the more you cost.

- Processing machine: Then it is key for you to choose a suitable set of fertilizer processing equipment according to your budget and production requirements.

How to reduce your cost on the mini organic fertilizer making business?

Among all the factors, which influences the cost, the fertilizer processing machine is key. If you choose complete machines for manufacturing organic fertilizer granules, the more the machine, the more you cost. Thereupon, you should prepare larger place for setting these machines. Then the cost on plant will rise. Meanwhile, the automation of fertilizer processing equipment also affects the labor force you need. The more automatic the machine, the less the cost on employees.

In a word, to reduce your dollar cost of purchasing a mini organic fertilizer production line, it is important for you to select suitable equipment configurations at low cost. Here Shunxin provides you different configurations for you to choose.

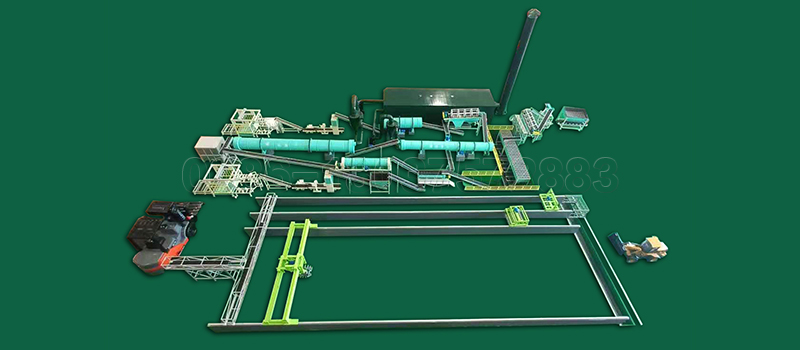

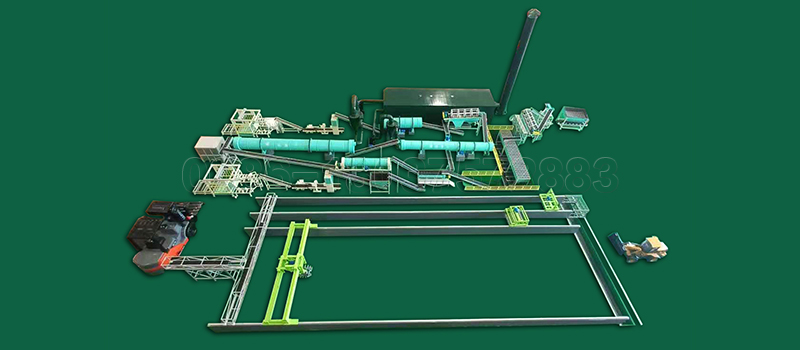

Shunxin hot sale small organic fertilizer production lines help you make fertilizer at lower costs

Generally, making commercial organic fertilizers, it is alternative for you to produce the powdery or granular fertilizers. For your mini organic fertilizer production line plant, there are two types of simple production lines in Shunxin for your reference.

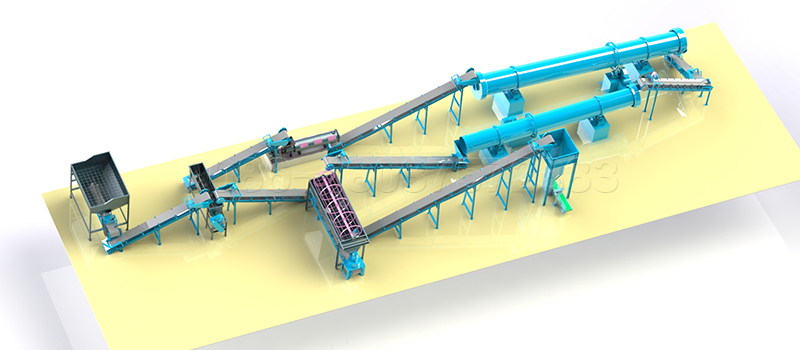

Small scale organic powder fertilizer production line for sale

Manufacturing organic fertilizers powder, the first step is composting. Composting can turn fresh organic materials into available organic fertilizers. But, for finer organic fertilizer powders making, a fertilizer crushing machine is crucial. Shunxin manure fertilizer grinder can help you make fine fertilizer powders. There are various pulverizers and specifications, which all adopt advanced designs for fine powder making.

For your high moisture content manure compost crushing, both the semi-wet pulverizer and vertical type crushing equipment are suitable, which have good reputations among our customers. And the vertical one has larger production capacity than the semi-wet one.

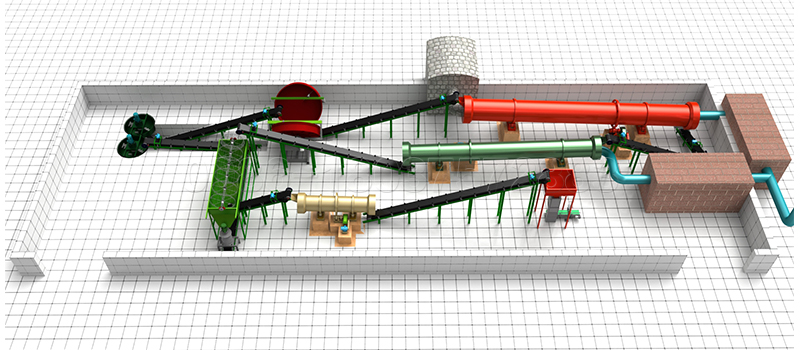

Shunxin cost-effective small capacity organic granular fertilizer production lines for sale

In a granular fertilizer production line, the granulating process is key. You can pelletize your crushed organic compost by using a fertilizer granulator. If your production capacity is small, which is about 0.5 ton to 1 ton per hour, our pan granulation machine is a good choice for you. Meanwhile, using this machine as pelletizer for making fertilizer granules, it is convenient for you to adjust the diameter of pelletized fertilizers. Besides, for your pure organic fertilizer pellet manufacturing, our patent organic fertilizer pelletizers are more suitable. It is mainly designed for manufacturing organic fertilizer granules dedicatedly. And the strength of manure fertilizer granular is harder than pellets made by disc pelletizer. You can use it for your 1 ton per hour organic waste fertilizer manufacturing.

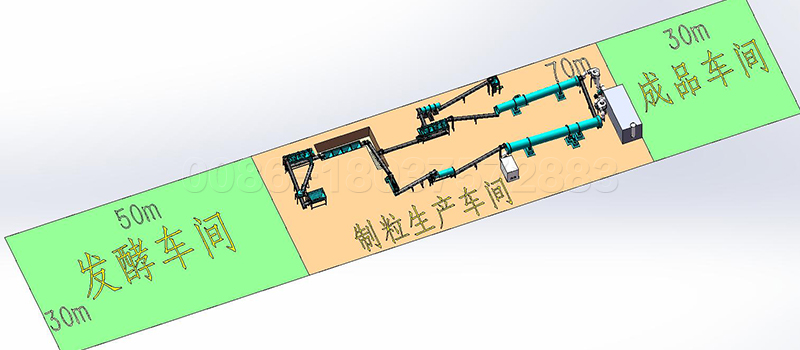

The above two mini organic fertilizer production line are simplest lines for manufacturing high-quality organic fertilizer machines, which is suitable for your small scale fertilizer making business. And there is also some other equipment in Shunxin for you to process fertilizer more efficiently. For example, there are moving type windrow turner for composting organic materials rapidly, which is convenient for moving and controlling and takes little place. Moreover, if you have other requirements on processing or machines, Shunxin tries our best to meet your needs. We can provide professional suggestions on your plant design and equipment configurations.